Applications for hydrostatic drives can be found in a wide range of sectors. They are also known as hydrostatic transmissions in some instances. A hydrostatic drive is frequently utilized if one or more hydraulic motors must be operated at various speeds with bi-directional capability.

Hydrostatic transmission lawn mower problems include Loss of drive, Old hydraulic fluid, Hot or cold hydraulic system, Overly Responsive, hydraulic malfunction, Drive pulley/belt breakage, Transmission overheating, hydrostatic Transmission pump failure. Air in the lines, Worn drive belt, Lack of lubrication, Hydraulic fuel leak.

Conveyors, log cranes, mobile equipment, centrifuges, chemo-washers, and planers are examples of typical applications. As a result of the fact that many of the components are found on or inside the hydrostatic pump assembly, hydrostatic drives are among the least understood systems.

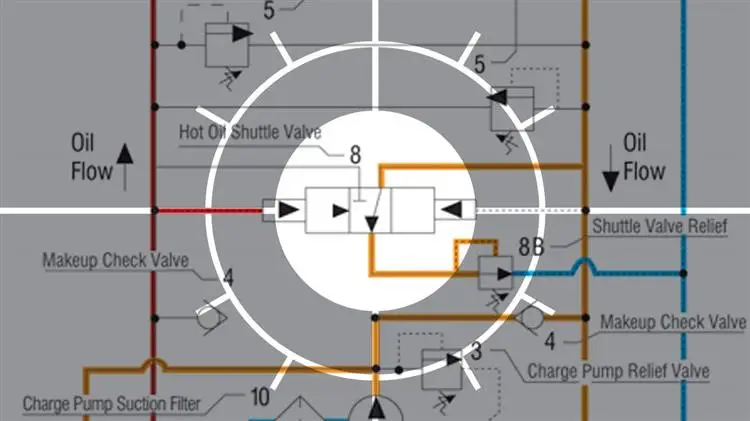

Figure 1 depicts a schematic of a common hydrostatic drive. A bidirectional, variable displacement pump manages the hydraulic motor’s direction and speed. A closed-loop system is a typical name for this kind of drive.

Hydrostatic transmission problems:

1- Loss of Drive:

If your hydrostatic transmission is not responding even at high throttle, there is unquestionably an issue because you would want a seamless and smooth shift even at low throttle input. As this is one of the most significant problems with hydrostatic transmissions, you would quickly feel and sense if the transmission was shifting slowly from one gear to another.

Solution:

Replace the transmission pressure sensor first, and if that doesn’t fix the problem, look for an oil leak in the gear’s servo assembly.

2- Old hydraulic fluid:

many of its properties when it sits for a long time (for instance, all winter), which might cause the transmission to fail. These lawnmowers usually always have an old fluid issue when they cease working. Flush the system before storing the mower for the winter if you notice that this issue typically arises when you start mowing in the spring.

Solution:

- Bring your lawnmower to a pro who will clean the lines and replace the worn-out hydraulic oil if you’re in a rush.

- But if you want to save money, you can do it yourself. Simply take off the drain cover to let the fluid drain all the way. At most, this process takes a few days.

- It’s time to re-oil the engine after you’ve removed everything.

- Make sure the lawnmower fluid you’re using is right for your machine. You can frequently locate the right blend by consulting the owner’s manual.

3- Hot or cold hydraulic system:

Hot Hydraulics System:

Operators frequently lament that their Cub Cadet SLT1554 or other models’ hydraulic system is running too hot. A hot hydraulic system can hinder lubrication and result in fluid leaks, so take this seriously. Additionally, it significantly affects the oxidation and thickness of fluids. As a result, your hydraulic fluid will thicken and permit systemic buildups.

Cold Hydraulic System:

If the hydraulic system in your Cub Cadet LT1050 or other model is too cold, your system is in grave danger. The hydraulic fluid initially thickens and is unable to reach the pump. Long-term heat transfer by the hydraulic system will be impossible, leading to system deterioration.

Solution:

- Try to stay as close to your mower’s limits as possible. On a scorching summer day, overusing the equipment could lead to overheating and malfunction. Additionally, avoid leaving it out in the sun for a lengthy amount of time.

- The mower should be kept in a slightly warmer place during the winter and should be started once a week.

When it comes to acceleration and gear selection, drivers of vehicles with hydrostatic transmissions must exercise extraordinary caution. Light pedal pressure might cause the car to move ahead uncontrollably. A small error in judgment could cause the car to lose torque and wobble. HST is therefore a rather constrained option. It is exclusively applied to automobiles like tractors.

4- Hydraulic malfunction:

Hydrostatic transmissions are leakage-proof systems, so anything seeping from them is undoubtedly an indication of a hydraulic issue that might cause you major problems down the road. You would experience a transmission fluid pressure error, such as P0842 or one in a related range. If these sensors detect low pressure, there may not be enough fluid in the transmission or a leak anywhere in the transmission.

Solution:

To address the P0842 code, a mechanic may attempt several repairs, including Replacing the pressure control solenoid. Refilling, or flushing and replacing, the old transmission fluid. Clearing blocked transmission fluid passages.

5- Drive pulley/belt breakage:

No matter what kind of lawnmower you have, the drive belt is necessary to move the machine forward. With this belt worn, operating your mower will undoubtedly result in a loud screech. If it’s broken, you won’t be able to move in any direction.

Solution:

No matter what kind of lawnmower you have, the drive belt is necessary to move the machine forward. With this belt worn, operating your mower will undoubtedly result in a loud screech. If it’s broken, you won’t be able to move in any direction.

6- Transmission overheating:

Because excessive heat can damage, wear out, and malfunction transmission gears and shafts. This causes the car to operate below what is acceptable, consume a lot of gasoline, and shorten the life of the gearbox’s mechanical parts. Hydrostatic transmissions typically display an error when they overheat. It takes a diagnostic tool to obtain these precise error codes because the fault is not instantly visible on the screen.

Solution:

Check the condition of the gearbox oil after the transmission has cooled. If it is overly thick and entirely black, change it. Check your clutch as well to see if that is the cause of the issue.

7- Hydrostatic Transmission pump failure:

The Ariens hydrostatic transmission is generally dependable, although it starts to lose effectiveness early in life, and as it ages, it becomes more difficult to produce pressure quickly. The performance of the vehicle’s shifting will be most impacted by this.

Driving will undoubtedly cause you to experience shifting problems, and in the worst-case scenario, complete failure. Only while driving at the specified speed and rpm will you notice this issue because it is a shifting failure.

Solution:

To fix this issue, the transmission oil pump typically needs to be changed because it is worn out. Additionally, it has been observed in some circumstances that this problem can be fixed by removing and rebuilding the oil pump.

8- Air in the lines:

Cavitation, or the presence of air in the system, can lead to issues with hydrostatic transmission. The pump cannot produce the necessary pressure when it is supplied with air rather than oil. This is rather common with hydrostatic gearboxes with zero-turn simplicity.

Solution:

- Before putting your mower away for the winter, it’s a good idea to drain the hydraulic oil. By doing this, you can steer clear of both problems and begin again in the spring. To clear the lines of air, do as follows:

- First, place the jack stands at the back of the mower and level the ground. According to the manufacturer’s recommendations, fill the oil reservoir. Cut the transmission off. As you’re moving, start the engine. Reduce the throttle setting while the engine is running. Disengage the clutch and brake pedals while in neutral.

- After that, advance the motion control levers for five seconds. For five seconds, retract the motion control levers. Five and six are repeated three times. The hydraulic transmission system should then be blown out. Turn off the controls. Stop the car by stepping on the parking brake.

- Next, check the oil and add more if necessary. The transmitter should be started. Start the engine, remove the jack stands, and let off the brake. The control levers should be advanced five feet. Reverse direction for almost the same distance. Repeat three times after resetting the levers.

- If you’ve followed all these directions, there shouldn’t be any more air in the lines. You can use the same oil with this procedure, which is less expensive than having a professional service your lawnmower.

9- Worn drive belt:

No matter what kind of lawnmower you have, the drive belt is necessary to move the machine forward. With this belt worn, operating your mower will undoubtedly result in a loud screech. If it’s broken, you won’t be able to move in any direction.

Solution:

The easiest approach to access the drive belt is often to remove the cutting deck. The owner’s manual for your vehicle should provide detailed instructions on how to do this. To expedite the procedure, it is also advantageous to have support on hand.

10- Lack of Lubrication:

The transmission gears may become sluggish and challenging to use if they are not properly lubricated.

Solution:

As instructed in the owner’s manual, check the level of the transmission fluid, and replenish it as needed. Look for reddish-colored fluid near the lawn tractor if the transmission fluid level is low, especially if you’ve just filled the reservoir.

11- Lack of Lubrication:

The mower might not be able to move forward if your oil lines are leaking. Here are a few warning signs of fluid leakage. Slow or jerky motions are signs of a leak, which means the lines are under pressure. Your lawnmower might not be as smooth as it once was. Spills of oil on the ground: When you move your lawnmower, you’ll notice a patch of hydraulic oil there, which is a sure sign that there’s a leak. The oil that leaks into the engine will burn off while you are mowing. A leak may be discovered by a powerful smell of white smoke.

Solution:

You must locate the leak’s source before you can tackle this problem. The following is a list of typical components that can leak over time.

- Gasket seals are vulnerable to wear and fracture since they are made of rubber. The seal should start to leak oil, which is a sign that it needs to be changed.

- Hydraulic oil is transported in lines that can be scraped or nicked, which might cause a slow leak.

- Crankcase gaskets: The crankcase is put under a lot of pressure, which over time leads to cracking or breaking. The shattered cap must be replaced even if the old seal is generally always the source of the leak.

How to repair broken Hydraulic Hoses and Seals:

- Check leakage:

If you discover oil dripping from a hose connection to the hydrostat, a leaky hose or seal is probably to blame.

- Try tightening the hose

Try tightening the hose first before attempting to remove it. A leak that develops from something as small as a 14 turn can eventually cause enough systemic drain to be problematic. If you discover this to be the case, perform the purge procedure and keep an eye on the leak. I’m hoping it will cease.

- check the seal condition:

You will need to either replace a seal or a hose entirely if the seal is completely gone or the hose is split.

- take the hose off

Use a wrench to remove the nut securing the hose to the hydro to accomplish this. You ought to be able to take the nut off and take the hose off. After that, check the hose’s end to see if the seal has been compromised. If so, you can replace the O-ring seal and put the hose back in place. If you are certain that the hose is split, repeat the removal procedure on both ends.

- install the hose

To keep the nut from coming free later, think about using thread lock before you install the hose. After that, reposition the hose and tighten the screw once more.

- get rid of the air

Run the purging procedure one last time to get rid of the air and, if necessary, top off the oil level. Since a lot of oil would have been lost and replaced with air, you might need to perform the purging procedure several times.

Conclusion:

All that’s needed to solve hydrostatic transmission issues are sporadic troubleshooting. You can restart your hydrostatic transmission by doing troubleshooting, except for really complex problems. A little technological know-how and a few tools are all you need.

Never forget that your machine’s usefulness and productivity are due to its hydrostatic transmission. Keep an eye on the system to prevent a last-minute rush for replacements and repairs. In conclusion, since those devices are your investments, have an expert manage your problems.

FAQ’s

· This is merely a potential oversight and not actually a repair. You can locate a long metal rod or pin coming from the hydro transmission on the back of the lawn mower.

· This may be marked with a label and feature a pull-out hoop on some lawn mowers. If you can move the lawnmower with the brake off, the drive has disengaged. The mower should return to drive if you push or pull the lever.

· Make sure you only use this with the brake engaged and the lawn mower turned off. If your mower is on an incline, take caution since the mower may roll away if your drive is already engaged and you release it.

Check for broken, worn, or missing idler tension springs, and bent or damaged belt idler brackets, and perform any necessary maintenance. If none of this work to solve the issue, the transmission’s internal parts might be to blame.

Flywheel accumulators have been used frequently with hydrostatic gearboxes. Their excellent efficiency and compactness are their key advantages. Their primary drawback is their expensive price, especially in applications using high-efficiency units.

The three methods of metering the oil flow to manage a cylinder’s speed are meter-in, meter-out, and bypass.

Leave a Reply