Basic details about the belt and its operation are provided by the Craftsman LT2000 drive belt diagram. The riding lawn mower belt must be kept in good shape for the machine to function as intended. The diagram also indicates when the belt needs to be replaced. It is crucial to have a nice, sturdy belt since it aids in spinning the blades and cutting the grass. You’ll have a hard time making your lawn seem good again if it malfunctions or breaks in any way.

On a Craftsman LT2000, the drive belt is joined to both the engine and the transmission. The transmission spins because of the belt spinning as the engine turns. The transfer of power from the engine to the wheels is made possible by this. This is what enables the mower to move by transferring power from the engine to the wheels.

Therefore, everything related to the Craftsman lt2000 drive belt diagram will be covered today what it is, how it works, why it’s vital, how to replace it, and more.

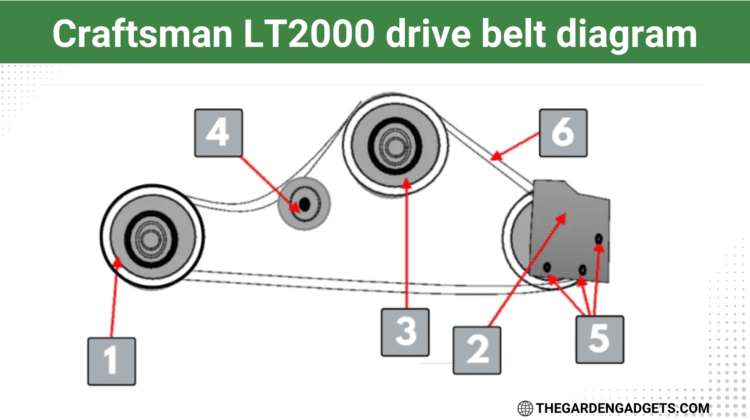

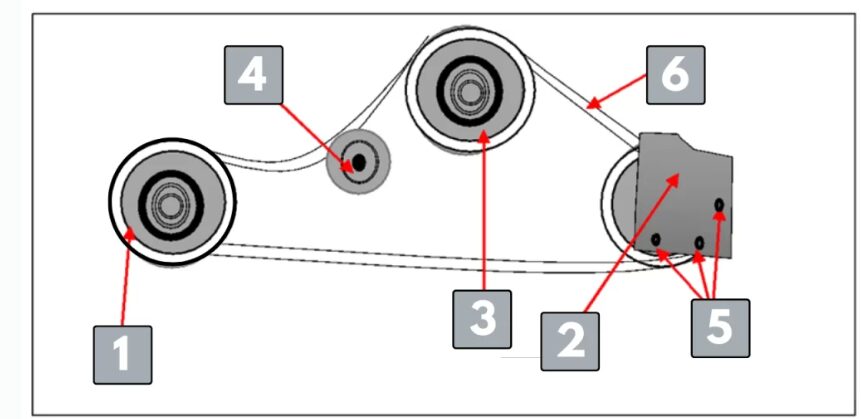

Craftsman LT2000 drive belt diagram explanation

The Craftsman LT2000 is a fantastic lawn mower for homeowners looking for a dependable and simple-to-use tool. The drive belt is one element that may make servicing this machine challenge. The machine won’t function correctly if this belt is not replaced because it can deteriorate with time.

Beginning with the drive-belt demonstration, let’s order all the topics in ascending order

The parts we have given numbers to in the prior diagram of the Craftsman LT2000 drive belt are described in greater detail here

| Moving Parts | How does it work? |

| Left Hand Double Pulley | Move heavy loads with less effort |

| Right Hand Double Pulley | Move heavy loads with less effort |

| Center Pulley | Help to hold the drive belt |

| Deck Idler Pulley | Maintaining tension on the drive belt |

| Self-Tapping Screw Assembly | Types of fasteners |

| Deck Belt | It connects the engine |

How Craftsman LT2000 Drive Belt Works

An essential component of the Craftsman LT2000 lawn mower is the drive belt. The drive belt’s main responsibility is to ensure that power is delivered to all of the mower’s components. This covers the wheels, blades, and engine. The engine shaft’s radial torque is additionally aided by the drive belt. This makes it possible for the blades to spin at a high rate, producing a lawn that is well-kept.

The engine will also be able to run thanks to the torque. There will be a connection between rotating the mower head and moving the propeller if the entire performance keeps running to and from work.

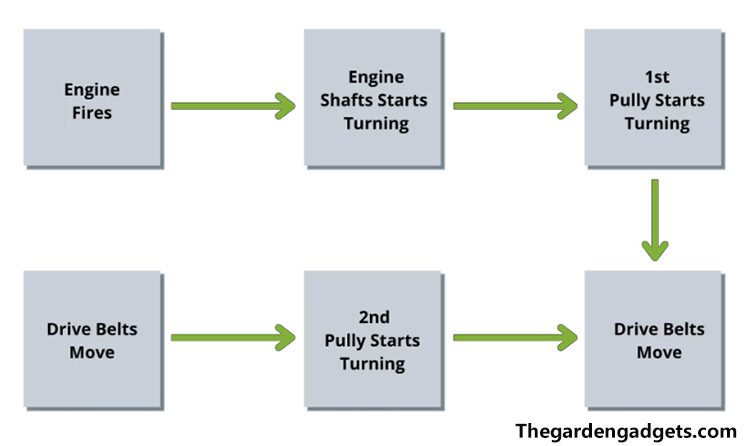

How Craftsman LT2000 Drive Belt Transfer Power?

Many folks don’t understand how a Craftsman LT2000’s drive belt may move power from the engine to the transmission. Some individuals believe that the belt is merely decorative and has no purpose in terms of assisting with the mower’s propulsion. Contrary to popular belief, the belt has a crucial role in transferring power from the engine to the wheels.

The drive belt is initially made possible to move by the first pulley, and the drive belt then causes the second pulley to move as well. When it is relocated to lead the transmission shaft as well, the second pulley’s connection to the input shaft is maintained.

Overall, in that way, the pattern is finished. The entire movement pattern is finished as a result.

Demonstration of the Craftsman Lt2000 drive belt power transformation

A power cable passed through the shaft and then to the driving wheels of each blade. This enables the blades to travel in a circular motion back and forth. As a result, this replicated how the drive belt from the engine made it possible for the mower to pivot.

How to replace Craftsman LT2000 Drive Belt

Lawn tractor ground drive belts join the transaxle pulley and the engine’s crankshaft. The mower’s back wheels are then propelled by this. The tractor cannot move if these belts are very worn or perhaps snap. Make careful to select a drive belt that has been approved by the manufacturer when buying.

Due to the low cost of replacement deck belts—under $20—this modification is not prohibitively expensive. These are much less expensive if you also require a Craftsman LT1000 drive belt.

It is essential to have step-by-step instructions available to prevent errors.

- Read the mower’s handbook

First, read the mower’s handbook. “Remove Mower” is clearly marked in the relevant section of the instruction manual.

- Remove the belt

Remove the belt from the clutch idler and stationary idler and Take the belt off the center span idler.

- Lift belt from transmission pully

Lift the belt gently upward from the transmission input pulley and from there above the cooling fan blades by pulling the belt slack to the back.

Pull the belt out of the pulley at the vehicle’s back Pull the steering wheel while dragging the tractor’s belt toward the back. It should be taken off the tractor’s top. - installing replacement belt

Install a replacement belt across the clutch pedal shaft and behind the front axle to the cutting bar.

- Adjust belt

Roll the belt onto the engine pulley by pulling it toward the front of the tractor. Pull the belt back until it stops close to the input pulley and the transmission cooling fan. Do this until the tractor is facing the rear. Ensure that the belt is securely fastened in the belt holder. Place a belt in the middle of the idler’s central span. Utilizing the stationary idler and grabbing the idler, attach the belt. Ensure that the belt is completely seated within all pulleys, as well as inside all belt guides and keepers.

Helpful Video Tutorial For LT2000 DRIVE BELT Replacemnet

Factors that Could Affect the Durability of a Craftsman LT2000 Drive Belt

Here are seven elements that can shorten a mower drive belt’s lifespan. If you want the lawn mower to last a long time, you must maintain the belt and run it properly.

Drive belt’s quality

The quality of the drive belt is what decides how long it will last. In other words, the projected lifespan increases with product quality. In any case, that is the general rule.

Neglecting the belt

The deck belt and driving belt both require similar maintenance. Therefore, allowing the belt to care for itself will result in a shorter lifespan.

Accumulation of debris

The driving belt pulleys are frequently exposed to a lot of trash from routine mowing. As a result, a buildup will start to form inside the pulley’s groove. The belt will have to travel a greater distance overall because of this buildup. To make up for this, the belt and tension spring both extend out.

Underneath most walk-behind and ride-on mowers are exposed drive belts. The lifespan of the belt is affected by what you subject it to

Distorted pulleys

The pulleys are vulnerable to damage because they are frequently exposed. As a result, yard debris can get into touch with the pulley and harm it to the point where the belt continues to sustain damage.

Strong Tensioner

The belt will move too much if the tensioner is weak. The drive belt can jolt and pass through the pulleys incorrectly thanks to this movement while it is under pressure. This incorrect operation causes the belt to deteriorate considerably more quickly and will eventually render it useless.

Violent Driving

Although aggressively hitting the accelerator may seem exciting, the drive belt regrettably has other ideas. The drive belt experiences extreme pressure as a result and stretches as a result. The belt overstretches because of continual belt extension brought on by frequent rapid acceleration. When this occurs, the tension spring must make up for it, but tension springs have the maximum amount of slack they can take.

Slower RPM engagement of the mower blades will help increase deck belt longevity.

Conclusion

The components and their roles in the drive belt system are depicted in the craftsman LT2000 drive belt diagram. A list of the pieces and their corresponding numbers, along with a description of each part’s purpose, are included in the diagram. The drive belt system’s entire mechanism is demonstrated in the diagram, along with the most often-asked questions regarding it.

We hope the information was thorough enough to provide all the solutions to the issues you were searching for. If not, then you should seek professional help and present them with the complete picture of the problem you want them to solve. Perhaps the issue is more complicated than it appears. And you should never delay in getting the repair done that your machine requires.

Frequently Asked Questions ( CRAFTSMAN LT2000 DRIVE BELT DIAGRAM )

Depending on who you ask and how they use their lawn mower, different people have different expectations for how long a mower drive belt should last. It depends on whether you take good care of your mower or if you’re aiming to break the land-speed record for lawn mowers. I’ve compiled all the elements I’ve encountered over the course of my years of lawn mowing and want to share them with you so you can get the same outcomes I have.

Your lawn mower drive belt should easily last three to four years. With the right care and upkeep, you can, however, prolong the belt’s lifespan past this.

The drive belt for the Craftsman LT2000 measures 1/2 x 95.5 inches. This is the size that your craftsman lt2000’s drive belt needs to be to be installed correctly. Before placing an order for a new belt, make sure to take the appropriate measurements of your old one. The improper size can cause installation issues and reduce your lawn tractor’s performance.

The answer is no, no alterations are necessary. Instead, the manufacturer advises merely changing the belt if it becomes worn or broken. The blade drive belt on these devices cannot be adjusted.

Leave a Reply